- Qingdao Woven Sound Acoustic Tech Co.,Ltd

- Tel: +86-532-87621678

- Mob: +8618954297931

- Email: max@wovensounds.com

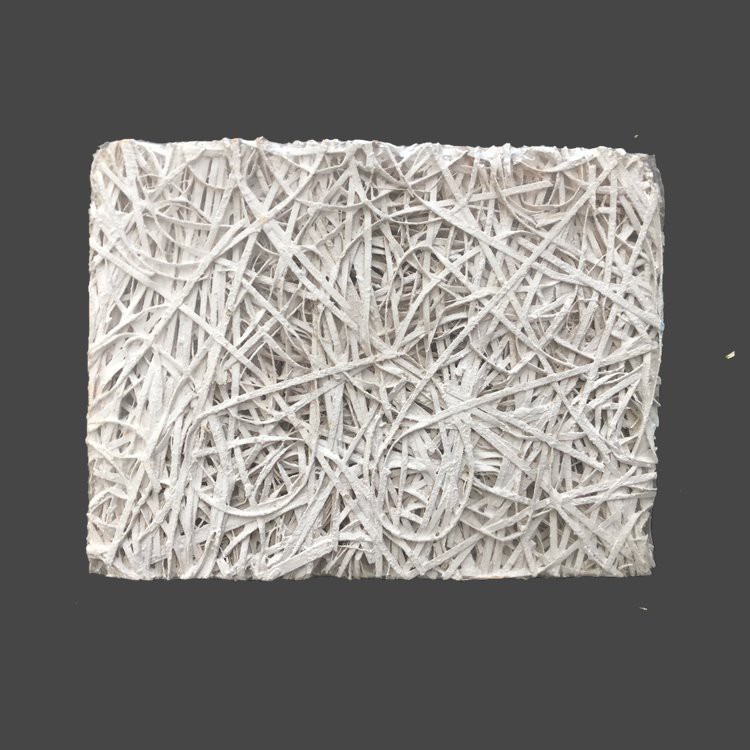

Wooden Fiber Acoustic Panel

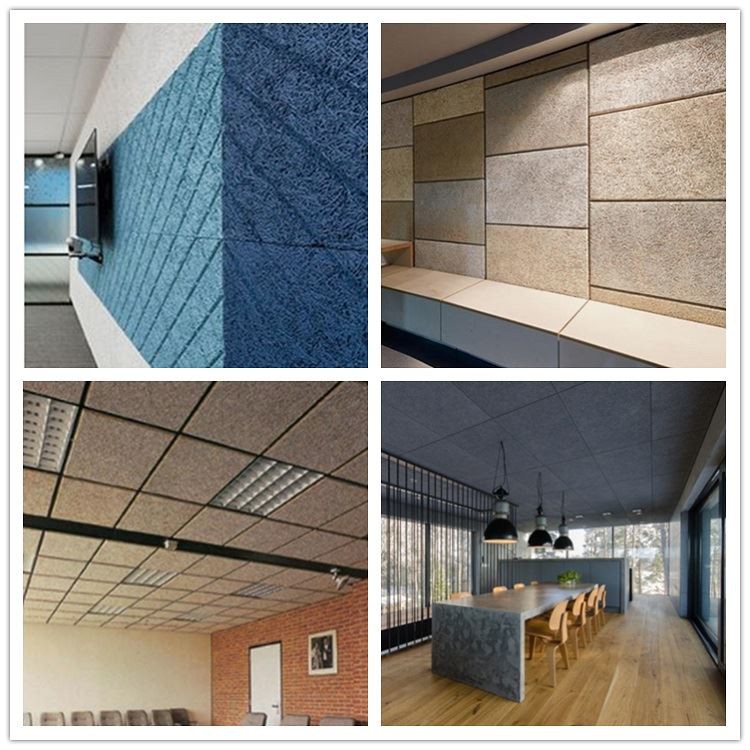

The surface texture of the wood wool sound-absorbing board shows an elegant texture and unique taste, which can fully interpret the designer's creativity and ideas.

Product Information

|

Brand Name |

Wooden Fiber Acoustic Panel |

|

Shape |

Square shape, Sculpted shape |

|

Edge |

Square |

|

Color |

Personalized print |

|

Size |

Base board size 2420x1220mm, 1200x600mm,600x600mm |

|

Thickness |

15mm 20mm 25mm |

|

Fire Rating |

GB8624-2006 B1 |

|

Acoustic |

GB18580-2001 E1 |

View the models here:

Product Characteristics

The surface texture of the wood wool sound-absorbing board shows an elegant texture and unique taste, which can fully interpret the designer's creativity and ideas. This product combines the advantages of wood and cement: it is as light as wood and as strong as cement. It has multiple functions such as sound absorption, impact resistance, fire resistance, moisture resistance, and mildew resistance.

Wood wool sound-absorbing board is made of wood fiber, combined with a unique inorganic hard cement binder, using a continuous operation process, under high temperature and high pressure conditions. The product has physical properties that can only be obtained by synthesizing several different building materials.

Unique appearance and good sound absorption-the unique surface silk texture gives people a primitive and rough feeling, which satisfies the modern people's idea of returning to nature. Surface can be painted

Applications

The product is used in places with relatively high requirements for sound quality and environment, showing a high-grade public image, adding a warm and harmonious business and office atmosphere. Applicable to the architectural field, including grand theaters, concert halls, stadiums, banks, securities firms, airports, star hotels, high-end office buildings, conference halls, negotiation rooms, reception halls and various cultural and entertainment venues.

Install:

The silk sound-absorbing board must be placed in the place to be installed for 48 hours to adapt to the indoor environment.

1. Wooden keel installation

The walls covered by the sound-absorbing panels must be installed with keels according to the design drawings or construction drawings, and the keels must be leveled. The surface of the keel should be flat, smooth and without deformation; the structural wall should be constructed in accordance with the building code, and the arrangement of the keel must be compatible with the arrangement of the sound-absorbing board; the spacing of the wooden keels should be less than 500mm.

2. Nail installation

In the case of installing the wooden keel, use nails to fix the keel from the side of the wood wool board. The nails should be evenly arranged and require a certain density.

3. Light steel keel

When the storey height is high or the fire protection level is high, the use of wood keel may not be allowed. During construction, small pieces of wood spacers can be fixed on the light steel keel with self-tapping screws, and then the wood wool board can be fixed to the wood chips. The specific construction method is the same as above, if it is directly installed on the light steel keel, it needs to be fixed with self-tapping screws.

FAQ:

1. What’s the price?

The price is negotiable. It can be changed according to your quantity or package. When you are making an inquiry, please let us know the quantity you want.

2. Can I get the sample free?

Sample is Free, but the freight cost is collected in advance.

3. What is the minimum order quantity?

1 sheet of each color. ( Sheet size: 2420x1220mm)

4. Can you do OEM?

Of course and welcome. You send us your design and LOGO, we can manufacture according to them.